Vision

becomes reality

Considering new ideas, evaluating possibilities, and then building a unique turnkey superconducting system. That is what we do and what we love. Please take a look at our former and current projects. Here you will find all information about our work. If you would like to know more, please do not be afraid to contact us.

3S -The worldwide first modular superconducting busbar

Installation in a chlorine electrolysis at BASF SE

Superconductors offer practically loss-free transmission of large quantities of electric power. Together with our partners Karlsruhe Institute of Technology (KIT), and the Institute of Air Handling and Refrigeration (ILK), we have developed the worldwide first superconducting modular busbar system for commercial applications.

The demonstrator has a current rating of 20 kA and a length of 25 meters. It has shown the potential of superconductors in an industrial setting; a chlorine electrolysis at BASF SE.

Considering aspects like space, safety, sustainability and operating costs, superconducting busbars offer significant advantages for many industrial applications that require large currents. The project was government-funded by the German Federal Ministry for Economic Affairs and Energy through Projektträger Jülich and is still in place and continuously revised.

DEMO200 - 200kA Current Lead

Installation in an aluminium smelter at Trimet SE

The DEMO200 project has successfully demonstrated the capabilities of superconducting technologies in high-current industrial applications. The initiative culminated in the development of a 200,000 A superconducting busbar system, which was installed and tested at the aluminum smelter operated by Trimet SE in Voerde. The project delivered a modular current lead system capable of handling extreme currents while seamlessly integrating with a sophisticated busbar structure.

A key achievement was the implementation of an innovative liquid nitrogen (LN2) cooling design, which ensured efficient and reliable operation under demanding conditions. The system's performance in a real-world industrial setting validated the potential of superconducting technology to revolutionize high-current applications.

The knowledge gained during this project has paved the way for scalable solutions, enabling superconducting systems to be adapted for a wide range of industrial applications. This success was made possible through the collaboration of leading partners, including the Karlsruhe Institute of Technology, Messer Group, and Theva, with funding from the Federal Ministry for Economic Affairs and Energy.

For more information and updates on the project, visit the DEMO200 homepage.

Superconducting Cables for Sustainable Energy Transition (SCARLET)

Developing and industrially manufacturing superconducting cable systems

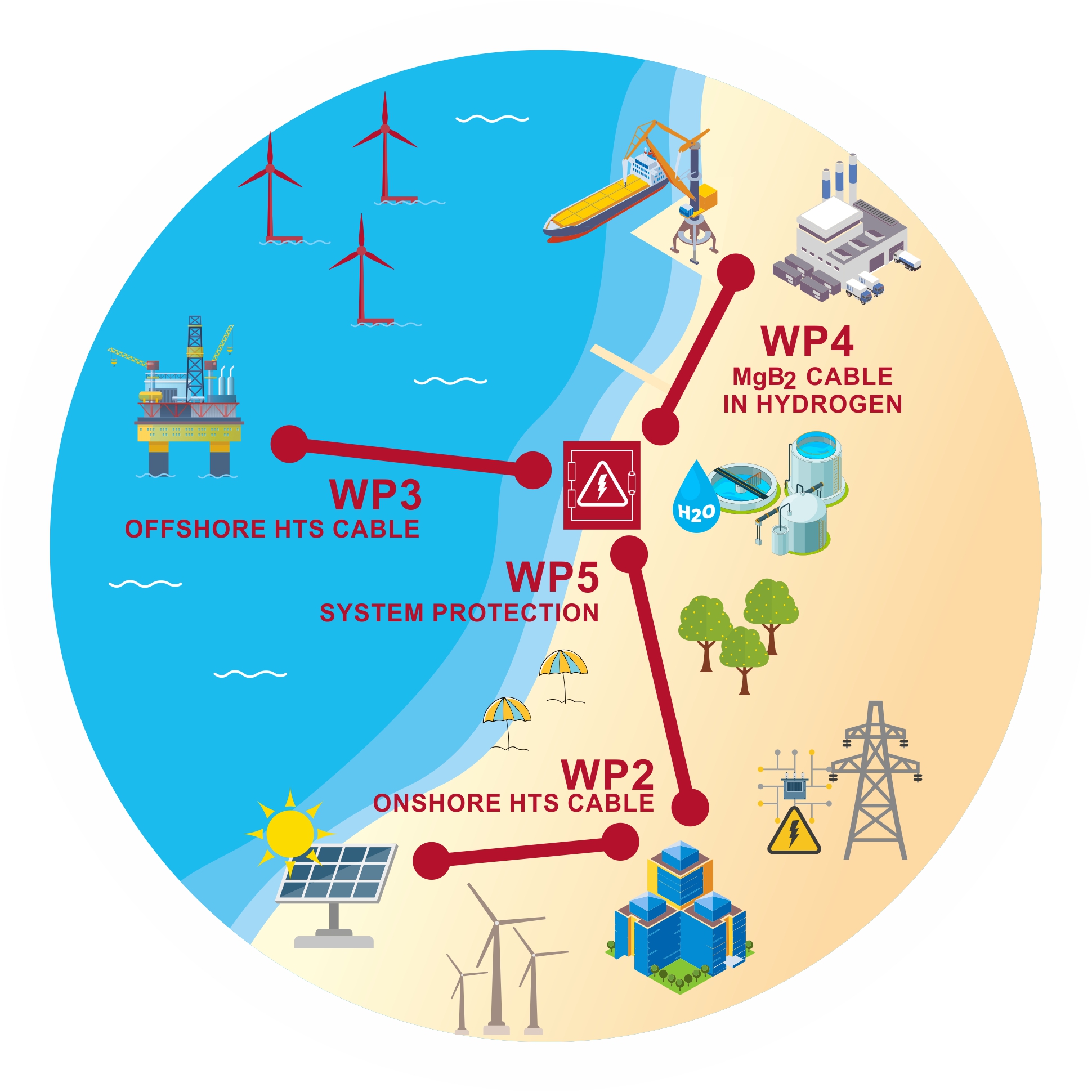

The EU project SCARLET (acronym for "Superconducting cables for sustainable energy transition") unites 15 partners from 7 countries around the goal of designing and industrially manufacturing superconducting cables in kilometric lengths. The 1 GW cable systems developed in SCARLET will be brought all the way to the type test, the last qualification step before a commercial installation.

An entire work package is dedicated to offshore superconducting links with innovative offshore cooling systems. Another work package is focussed on hydrogen-cooled superconducting cables, which open up the unique possibility of simultaneously transporting both hydrogen and electricity.

Funding statement: This project has received funding from the European Union's Horizon Europe research and innovation programme under grant agreement No. 101075602.

For more information visit: https://scarlet-project.eu/